For the test, an 18,000-pound pallet, simulating

the actual X-38, was dropped from the back of a C-130 aircraft

at an altitude of 21,500 feet. A 28-foot diameter extraction

parachute pulled the test platform from the aircraft at an

air speed of 130 miles per hour to begin the flight test.

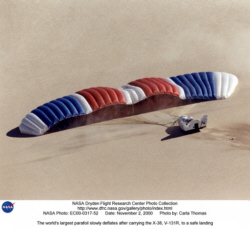

Once out of the aircraft, a newly designed 80-foot diameter

drogue parachute stabilized and slowed the platform to a vertical

airspeed of 62 miles per hour and enabled the parafoil to

begin a five-stage deployment process. During its 11-minute

long flight, the parafoil slowed the test pallet to a gentle

vertical landing speed of less than eight miles per hour.

"This parafoil is so big there is no way that it can

all deploy at once," said Brian Anderson, X-38 Project

Manager. "Because of its size, the dynamic forces on

the parachuteís structure are phenomenal." The

size of the parafoil posed technical challenges for the X-38

team. One problem encountered in past tests has been to ensure

that the parachute opens evenly. To solve this and make certain

that the parachute opens symmetrically and rapidly, the team

developed a revolutionary self-sealing floor vent system on

the parafoil's underside. During the recent test, the parafoil

opened to its full size in only 30 seconds. The parafoil was

stitched together at Pioneer Aerospace's facility in Columbia,

MS. Because of its |

|

|

Project Description:

The X-38 Crew Return Vehicle (CRV) research project is

designed to develop the technology for a prototype emergency

crew return vehicle, or lifeboat, for the International

Space Station. The project is also intended to develop a

crew return vehicle design that could be modified for other

uses, such as a joint U.S. and international human spacecraft

that could be launched on the French Ariane-5 Booster.

The X-38 project is using available technology and off-the-shelf

equipment to significantly decrease development costs. Original

estimates to develop a capsule-type crew return vehicle

were estimated at more than $2 billion. X-38 project officials

have estimated that development costs for the X-38 concept

will be approximately one quarter of the original estimate.

Off-the-shelf technology is not necessarily "old"

technology. Many of the technologies being used in the X-38

project have never before been applied to a human-flight

spacecraft. For example, the X-38 flight computer is commercial

equipment currently used in aircraft and the flight software

operating system is a commercial system already in use in

many aerospace applications. The video equipment for the

X-38 is existing equipment, some of which has already flown

on the space shuttle for previous NASA experiments. The

X-38's primary navigational equipment, the Inertial Navigation

System/Global Positioning System, is a unit already in use

on Navy fighters. The X-38 electromechanical actuators come

from previous joint NASA, U.S. Air Force, and U.S. Navy

research and development projects. Finally, an existing

special coating developed by NASA will be used on the X-38

thermal tiles to make them more durable than those used

on the space shuttles.

The X-38 itself was an unpiloted lifting body designed

at 80 percent of the size of a projected emergency crew

return vehicle for the International Space Station, although

two later versions were planned at 100 percent of the CRV

size. The X-38 and the actual CRV are patterned after a

lifting-body shape first employed in the Air Force-NASA

X-24 lifting-body project in the early to mid-1970s.

The current vehicle design is base lined with life support

supplies for about nine hours of orbital free flight from

the space station. ItÕs landing will be fully automated

with backup systems which allow the crew to control orientation

in orbit, select a deorbit site, and steer the parafoil,

if necessary. The X-38 vehicles (designated V131, V132,

and V-131R) are 28.5 feet long, 14.5 feet wide, and weigh

approximately 16,000 pounds on average. The vehicles have

a nitrogen-gas-operated attitude control system and a bank

of batteries for internal power. The actual CRV to be flown

in space was expected to be 30 feet long.

The X-38 project is a joint effort between the Johnson

Space Center, Houston, Texas (JSC), Langley Research Center,

Hampton, Virginia (LaRC) and Dryden Flight Research Center,

Edwards, California (DFRC) with the program office located

at JSC. A contract was awarded to Scaled Composites, Inc.,

Mojave, California, for construction of the X-38 test airframes.

The first vehicle was delivered to the JSC in September

1996. The vehicle was fitted with avionics, computer systems

and other hardware at Johnson. A second vehicle was delivered

to JSC in December 1996.

Flight research with the X-38 at Dryden began with an unpiloted

captive-carry flight in which the vehicle remained attached

to its future launch vehicle, DrydenÕs B-52 008.

There were four captive flights in 1997 and three in 1998,

plus the first drop test on March 12, 1998, using the parachutes

and parafoil. Further captive and drop tests occurred in

1999. In March 2000 Vehicle 132 completed its third and

final free flight in the highest, fastest, and longest X-38

flight to date. It was released at an altitude of 39,000

feet and flew freely for 45 seconds, reaching a speed of

over 500 miles per hour before deploying its parachutes

for a landing on Rogers Dry Lakebed.

In the drop tests, the X-38 vehicles have been autonomous

after airlaunch from the B-52. After they deploy the parafoil,

they have remained autonomous, but there is also a manual

mode with controls from the ground.

|

|